While doing research for an unrelated story, Travis came across a SRAM patent application for what looked like a two-speed hub. But the more he read, the more it seemed like this isn’t meant as a copy of the Classified Powershift hub. It’s something much weirder.

SRAM has applied for a complex patent involving a hub similar to one made by Classified. The document I’m using as a source was filed in Europe, and was published in April of 2025. I’ve found other documents saying the process was started in the US as far back as September of 2023, though I couldn’t find anything published at uspto.gov. Maybe it’s too soon, maybe it’s been abandoned, maybe I don’t know how patents work, maybe all three.

Anyway, the title is “BICYCLE WHEEL HUB, BICYCLE DRIVE TRAIN AND METHODS FOR THE USE THEREOF.” I found it on patentguru.com under publication number US20250100648A1, but you may need a (free) Patent Guru membership to view the document. You can also find it at this European Patent Office web page. With “EP All Documents” highlighted in black on the left menu, click on “Priority document” on the list of links. That includes everything I sourced for this story.

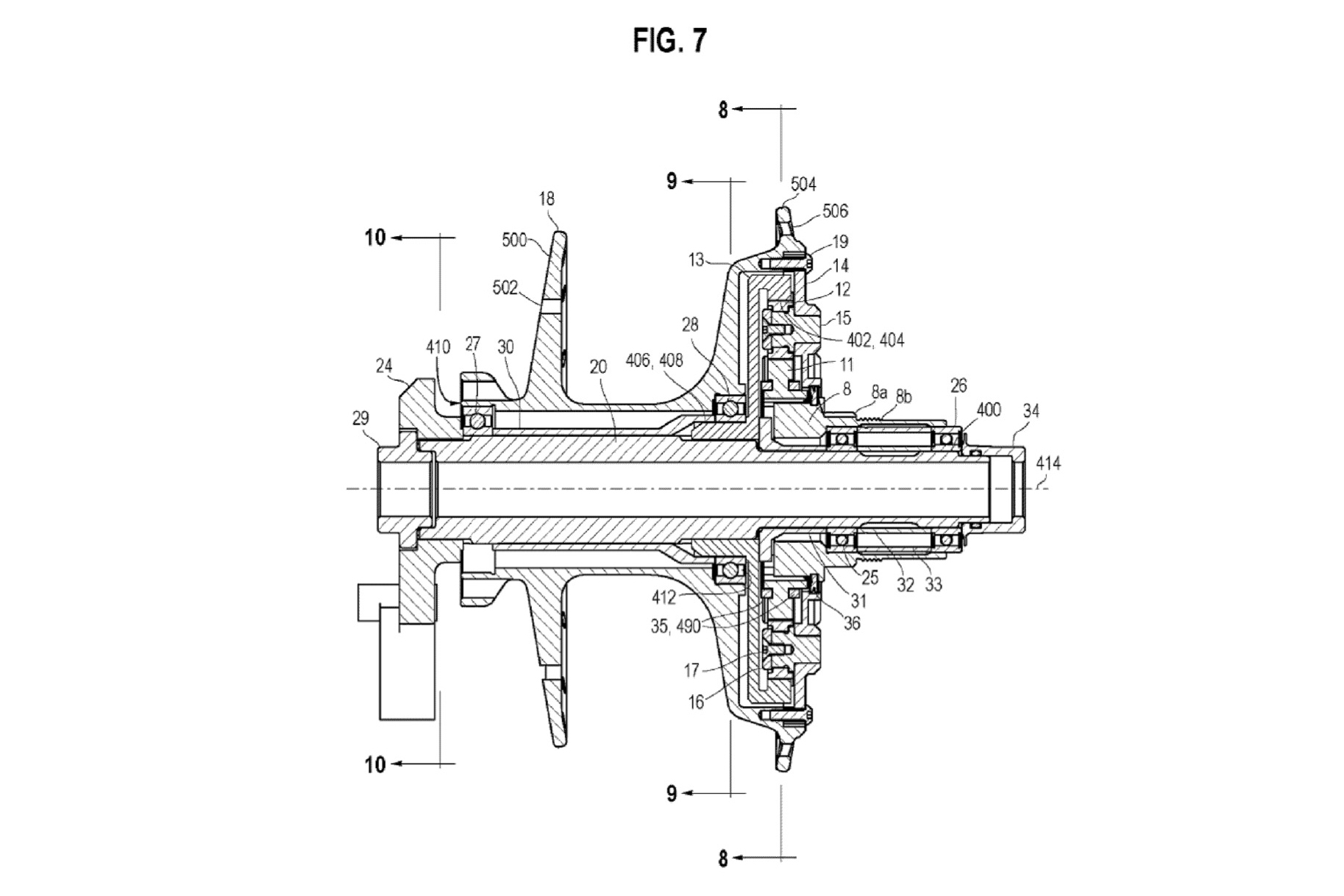

As a refresher, the Classified Powershift hub is a wireless two-speed system that either fixes the cassette to the hub for a 1:1 ratio, or engages its internal planetary gears to create a lower 1:1.4 ratio. On the surface, SRAM’s proposed hub appears to be similar. It’s got planetary gears inside, a normal-looking cassette outside, and even a little torque arm resting underneath the non-drive dropout to keep the axle from twisting. But the patent application goes well beyond just the hub and its inner workings.

For one thing, not all the images were of the hub itself. One was a complete bike, another was a high-pivot drivetrain, another seemed to be a crank gearbox. And everything was pointedly e-MTB-coded. That’s very much not our beat at The Radavist. Nor is patent speculation, to be honest. But I was intrigued.

Patent documents are dense. It took me a while to get past all the legalese. When I did, there was very little in there about a multi-speed hub’s capacity to widen your gear range like a Classified hub can. In fact, there was a lot of talk about the drivetrain as a whole. In the “Background” section that sets the stage of most patent documents, this application describes with surprising brevity how a drivetrain works. It moves on immediately to a topic SRAM seems to care a lot about:

“Shifting under load, however, may create high tension in the chain, which may adversely affect the quickness and smoothness of the gear shift, and may increase wear and the possibility of damage to the drive train. The challenges of high chain tension may be exacerbated when the bicycle includes an electric motor to assist in cranking.”

Also under the Background subhead, the document makes mention of gear-ratio-reducing hubs as well as gear-ratio-enhancing cranks. Of course, this made me think of Hammerschmidt. Long before Eagle, this was a single-chainring concept that used planetary gears to accelerate a 22- or 24-tooth ring faster than the crank for a higher gear, or to fix it to the crank for a lower gear. So, this SRAM patent application seems to combine these two systems as not-so-briefly described below. And if you stumble as much as I did on some of the vague patent language, “closed loop component” means “chain,” and “user input component” means “crank.”

“…unlike a typical bicycle drive train in which the chain ring rotates at the same angular velocity, or rotational speed, as the user input component, the first gear train between the user input and the chain ring causes the chain ring to rotate at a greater angular velocity than the user input component. Thus, the closed loop component [ ] moves faster, and has a lower tension, than a typical bicycle chain, resulting in reduced drive train wear. Because the closed loop component moves faster than a chain in a conventional bicycle configured without a gear train, the cassette rotates faster than a typical cassette, and therefore shift speed is increased due to the fact that shift gates on the cassette interact with the closed loop component more frequently.”

The hub’s role in this is mentioned later in the SRAM patent application.

“In one embodiment, the gear ratio of the first gear train may be the inverse of the gear ratio of the second gear train. In other words, the degree to which the chain ring spins faster than the user input component is “cancelled out” by the degree to which the hub shell rotates slower than the cassette. As a result, the rear wheel rotates at an appropriate angular velocity relative to the angular velocity of the user input component.”

Another segment brings it all home.

“As a result, the load input on the drive train is reduced to prevent damage during shifting and reduce the perception of rough shifting under load.”

Get it? The chain is spinning faster and is under less load, which means it can shift with less potential for damage, and will pass shift ramps more frequently meaning it can shift faster. The reduction in the hub means the wheel spins at a normal speed, and the reduction in the drive unit means the cranks spin at a normal speed.

Of course, there are a few reasons why this is being proposed in an e-bike scenario. For one, it’s harder to prevent loaded shifting on e-bikes. In the words of the document, “Due to control system limitations, the motor may continue to momentarily apply torque to the drive train after a user has reduced their torque input in preparation to command a shift.” Also, both SRAM and Shimano offer auto-shift settings on e-bikes using their motors and their electronic drivetrains. Whether or not that’s a stupid idea is beyond the scope of this article.

The other reason it’s being proposed on an e-bike is that the rider is less likely to notice the drag that will come with adding two gearboxes to the equation. The Classified hub’s drag isn’t that bad, but the Hamerschmidt’s drag definitely was. Though there already is a gearbox inside an e-bike’s drive unit to reduce the high-RPM, low-torque motor speed to a useful level, so maybe that reduction could be absorbed into what’s already in action. Regardless, there’s another embodiment mentioned in the document that seems to be meant for high-pivot bikes. See if you can follow along with this one.

“A method of propelling the bicycle includes rotating the crank arms about a first axis at a first rotational speed, simultaneously rotating the chain ring coupled to the crank arms, by way of a gear train, about a second axis, which may be coaxial with the first axis, at a second rotational speed greater than the first rotational speed, simultaneously rotating a gear (e.g., the cassette) about a third axis at a third rotational speed, wherein the gear is coupled to the chain ring with a closed loop component, and simultaneously rotating a wheel about the third axis at a fourth rotational speed less than the third rotational speed.”

This approach uses two chains like the Pivot Phoenix high-pivot downhill bike. But the upper input ring is smaller than the upper output ring, which makes the chain move faster. Then, as described, it meets a gear-reduction hub for normal wheel speed. That may be because this SRAM patent application, like all patent applications, casts a wide net so that someone can’t sidestep the patent with what’s described above. Also, the two-chain method seems like it would make it hard to achieve something else that’s described in another part of the document.

“It should be noted that in the event that the motor is unable to assist the rider (for example, if the battery loses power), the motor clutch will be “over run” by the rider’s pedaling, meaning that when the output shaft is driven by the rider, the output shaft does not drive the first and second epicyclic gear stages (i.e. the motor gear stages), thus eliminating undesirable pedaling drag that would arise if the motor epicyclic gear stages were required to operate.”

So, if the motor dies, your torque doesn’t have to go through this Rube Goldbergian process before it reaches the back tire. Or, at least not all of it. The system could eliminate the increased ratio of the front ring, but maintain the decreased ratio of the rear wheel. It’d be a contingency plan where you have an ultra low gear if you have to pedal an unassisted e-bike. And of course, the document mentions this could be done voluntarily:

“In another embodiment, when engaged, the gear ratio is always greater than 1:1. In an embodiment, [ ] an actuator (or locking actuator) allows a rider to reversibly disengage any one or a combination of the gear trains so that the respective gear train operates at a 1:1 ratio.”

So, the rider could voluntarily “shift” the hub, chainring, or both if they wanted. But this is the only mention I could find of this being a method for shifting a bike. The idea behind a Classified hub is to have access to a big immediate gear change that can happen under load, as well as to have closer gear steps without sacrificing overall range. The idea behind Hammerschmidt was to get a wider gear range in the days before cassettes surpassed 50 teeth. This patent application, despite all its wordy details, doesn’t appear to highlight either of those capabilities. Though if it gets approved, this SRAM patent application could theoretically allow them to make two-speed hubs for multiple purposes.